Hydro fracture grouting is the deliberate fracturing of the ground (soil or rock) using grout under pressure. Compensation grouting is the responsive use of compaction, permeation or hydro fracture grouting as an intervention between an existing structure and an engineering operation. Methods of pressure grouting that have proven to be effective are describe and various types of grouts and their properties are listed.

This grouting process is one of the best tools to improve the foundations of structures. On shallow applications, it can be injected from the top down. The composition of the material is one that water is not a component of the cured foam structure. Jet grouting is one of the most popular ground improvement techniques due to its applicability in almost all soil types. In this overview, the historical progress of technology development in jet grouting is briefly describe followed by the trace of the development of empirical and theoretical approaches.

Jet grouting is a method of soil stabilization which involves the injection of a stabilizing fluid into the subsoil (or the soil under treatment) under high pressure under high velocity. The injection process involves a certain amount of site preparation as well as injection equipment. It involves filling any cracks, joints or void in rock, concrete, soil and other porous materials. Mechanical locks can be welded to the inside cavity area to help prevent this problem.

Filling the inside cavity area with epoxy grout is a more expensive metho but it is typically better performing and maintenance free. Information on procedures, materials, and equipment for use in planning and executing a grouting project is include and types of problems that might be solved by pressure grouting are discussed. Mixing and blending tanks. The process of epoxy grouting is quite simple. The basic process of all grouting methods is same.

Only the material used to prepare the adhesive mixture varies from m. The compaction grouting method is one of the conventional ground improvement methods , which consolidates and compacts the surrounding ground through the injection of grout materials with low mobility. This method churns the grout and introduces air into the mix. That weakens the cured strength and causes a type of discoloration called “shading. Besides, we’re trying to mix grout here, not make soufflé. Grouting 1) Grouting method (1) The consolidation grouting should be conducted in accordance with the principle of the sequence and the density.

The different rows of the grouting holes and the different holes of the same row can be divided into two sequences construction, and also can be sequenced only by row but not hole or otherwise the opposite. Standard Test Method for Slump of Hydraulic- Cement Concrete, ASTM C 1(ref. 4), provides test procedures to test grout slump in either the laboratory or the field.

When the water flowing from the uncapped holes clears up, indicating the removal of the unconsolidated materials, the caps are removed to another pattern of holes. Place minimum recommended water ratio into the mixing container Progressively add the powder whilst mechanically mixing using a heavy duty low speed (3to 4rpm) electric drill or mortar mixer. Jet grouting is a well-established technology for shallow applications and use for the deep vadose zone can be extrapolated from the shallow zone practices. Because jet grouting information is readily available for use in feasibility studies, this evaluation focuses on permeation grouting for application in the deep contaminated vadose zone. Pour the mixed grout into the prepared area such that the grout has the shortest distance to travel.

Ensure that air displaced by the grout is allowed to escape. When carrying out base plate grouting , ensure sufficient head of pressure is maintained to keep mortar flowing. Grouting Methods Most water well grouting methods were developed by the oil well drilling industry. As water well drillers and public health officials became aware of the benefits of grouting , oil well grouting techniques were adapted for the water well industry. Soil grouting is an often misunderstood and overly simplified technology.

This misunderstanding can result in inadequate design and construction methods. And don’t mix grout with a drill and mixing paddle. Let the grout “slake” When your grout has reached peanut butter status, stop!

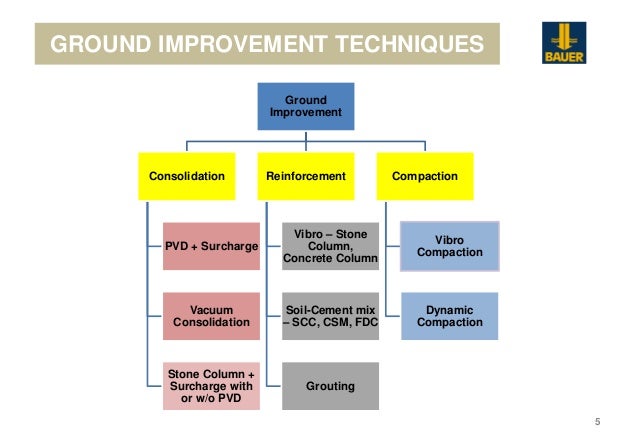

Grouting can be defined as controlled injection of material, usually in a fluid phase, into soil or rock in order to improve the physical characteristics of the ground.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.