Cable Tray Installation Guidelines. Addresses shipping, handling, storing and installing cable tray systems. Information on maintenance and system modification is also provided. To properly evaluate a cable tray wiring system vs. The NEMA VEpublication was written by a committee of member cable tray companies and defines the industry standard for cable tray installation.

The publication is intended as a practical guide for proper installation of cable tray systems. Not all steel wire cable trays are the same. Other installations , such as buried and aerial, have different installation parameters. LADDER TRAY IS A MECHANICAL SUPPORT SYSTEM FOR CABLES AND IS NOT TO BE USED AS A WALKWAY, LIFTING APPARATUS OR LADDER. This article is intended only as a practical guide for installers and its intent is not to cover all the possible contingencies encountered on site.

Cablofil wire mesh cable trays are constructed of precision engineere high-quality, welded steel wire and are the result of decades of research gained from the installation of 90miles of cable trays across the globe. How to install cable tray? Is innerduct required for fiber installed in cable tray? Are cable trays and cable racks the same?

Can cable tray system be used to support lighting fixtures? These guidelines will be useful to engineers, contractors, and maintenance personnel. Ongoing periodic reviews will be done to reflect advancing technology and construction techniques. Per NEC 39 the national electrical code section for cable tray , all cable tray systems must be properly BONDE per section 259. Section Maintenance is the final section covers inspecting, removing inactive cables and adding cables to existing cable trays.

NEMA VEcable tray installation guidelines are used for all types and materials of cable tray such as ladder, trough, center rail, wire basket in aluminum, steel or fiberglass material. Individual rungs will support without collapse a 2lb. In addition, its design does not contribute to potential safety problems associated with other wiring systems. Chalfant Manufacturing Company proudly manufacturers its cable trays right here in the USA. In fact we just recently expanded our manufacturing capabilities with a second USA production plant.

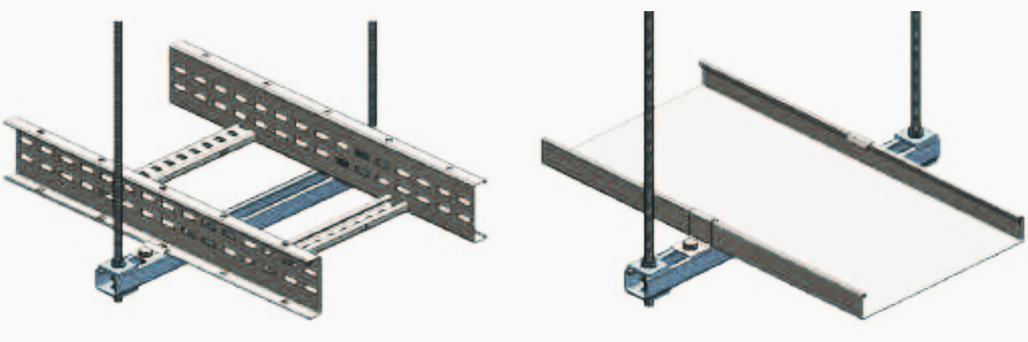

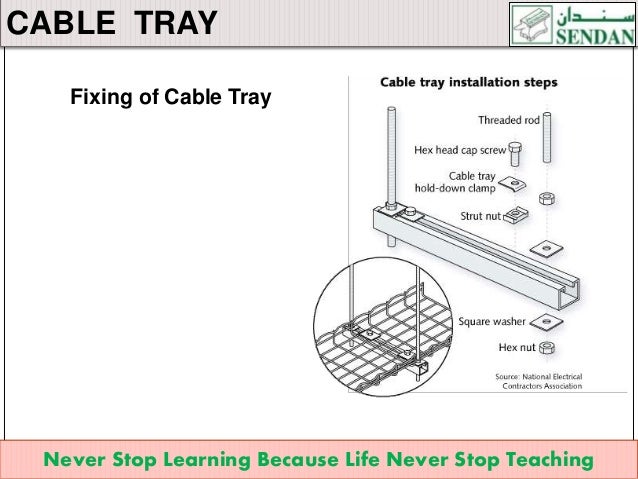

The new design eliminates to 75. A new EzyTray installation example to show you. In this photo the installer has cut the cable tray to work around other items in the site and has secured the tray to the wall with slotted strut. Horizontal lengths are supported by slotted strut acting as a trapeze which are in turn supported with threaded rod. Certain elements of the installation are cable vendor product specific, such as cable bend radii of the cable and component assembly detail.

In these instances the Standards refer to the cabling manufacturers product instructions. For Nexans products, please see the relevant data sheets for specific details. Content on this page requires a newer version of Adobe Flash Player. The amount of cost savings depends on the complexity and size of the installation.

Installation of divider strips a) These divider strips shall be installed where different system wiring is installed in a common tray or where shown in the design drawings.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.