When the electrode is positioned close to the work piece, an arc is created across the gap between the metal and the hot cable electrode. What is full form of arc welding? The plasma welding consists only of the plasma- arc welding process which works with a transferred arc.

The process uses shielding from an externally supplied gas to protect the molten weld pool. It uses a consumable electrode of a spool of wire that is continuously fed throughout the process. Arc welding is one of several fusion processes for joining metals. The process is commonly used in industry, especially for large products and in the manufacture of welded pressure vessels. A main objective became to develop and maintain a range of welding equipment that is suitable for onboard welding , backed by a worldwide service network, training and documentation.

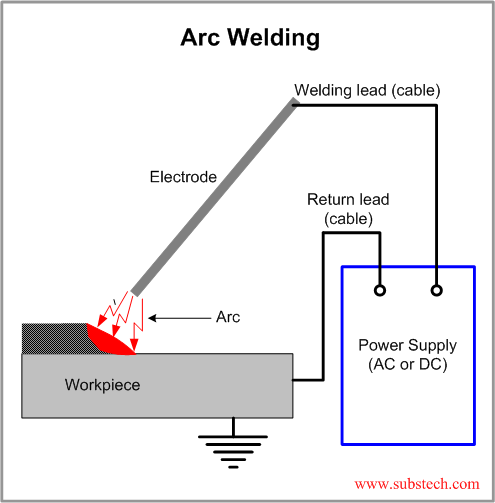

The basic principle of arc welding is shown in below Fig. This method is probably the most popular type of welding process since it includes many of the most popular types of welding , such as MIG, TIG, and Stick welding. The metal shielded-gas welding is limited to the metal inert-gas welding process operating with an inert gas as shiel as well as a process combination with plasma welding (plasma metal shielded-gas welding - PMIG). Plasma is a gaseous mixture of positive ions, electrons and neutral gas molecules. The welder creates an electric arc that melts the base metals and filler metal (consumable) together so that they all fuse into one solid piece of metal.

Steel Pipe –Tack Welded Root Pass or “Stringer Bead” Final weld after several beads are made. Flux covers weld zone in front of wire Heat of the arc melts the wire, flux and plate Fused flux shapes and protects weld metal Weld metal. Supplies electrical power to the electrode -The heat of the arc melts the electrode and base plate to form the weld bead. Gas tungsten arc welding (GTAW), or tungsten inert gas (TIG) welding , is a manual welding process that uses a nonconsumable tungsten electrode, an inert or semi-inert gas mixture, and a separate filler material.

There are many variations of the arc - welding process. Since the joining is an inter-mixture of metals, the final weld joint potentially has the same strength properties as the metal of the parts. Other fusion- welding processes.

By applying intense heat, metal at the joint between two parts is melted and caused to intermix - directly, or more commonly, with an intermediate molten filler metal. Upon cooling and solidification, a metallurgical bond is created. The core wire conducts the electric current to the arc and provides filler metal for the joint. Arc - welding processes 1base metal, A r - shield gas, and certain other conditions which may affect the position of the operating range in the domain. Several points should be noted.

Two of the most important processes use a gas shield to protect the weld metal from atmospheric contamination. The arc is the technological tool in the arc welding process. Improved welding quality requires precise control of the arc in all different welding phases. Production of this book to welding was prompted originally by a wish for an up-to-date reference on applications in the field.

The content has been chosen so that it can be used as a textbook for European welding courses in accordance with guidelines from. During the welding process the electrode, the arc and the weld pool are protected against the damaging effects of the atmospheric air by an inert shielding gas. By means of a gas nozzle the shielding gas is lead to the welding zone where it replaces the atmospheric air. Welding Processes Handbook PDF by Klas Weman. In this welding process, the electrode is having carbon material (Carbon rod)and it consist of negative pole and work piece as positive pole.

Source Extraction Equipment. Mechanical ventilation is an effective method of fume control for many welding processes. Because it captures fume near the arc or source of the fume, which is more efficient in most cases, local exhaust, also called source extraction, is a very effective means to control welding fume. This tungsten electrode is made use of to heat the base metal and create a molten weld puddle.

By melting two pieces of metal together, an autogenous weld can be created.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.