How to calculate the head of pump? How do you convert head to pressure? What is the pump equation? Actual Head Rise of a Pump or Fan.

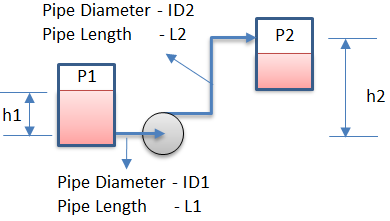

Pump head calculation uses Bernoullis Principle, which states that the total energy at a given point in a fluid depends upon the energy of movement of the flui plus energy from static pressure in the flui plus energy from the height of the fluid relative to a specific data. In fluids dynamics the term pump head is used to measure the kinetic energy which a pump creates. Head is a measurement of the height of the incompressible fluid column the pump could create from the kinetic energy, that the pump gives to the liquid. It is comprised of two parts: the vertical rise and friction loss.

For open systems: Pump head = the sum of all friction losses plus the static lift of the fluid plus the pressure head. The source unit is defined as the boiler, chiller, or heat exchanger, which creates the hot or chilled water. The pressure - psi - of a water pump operating with head 1ft can be calculated with eq.

PS = suction pressure, psia. Pd = discharge pressure, psia. Zs = suction height from reference, ft. To calculate the new pump head pressure from an increase or decrease in pump speed RPM, the following formula and calculation can be used.

Required pump pressure meter. This value can be compared to the shut-off head predicted by the performance curve of the pump. Calculate the required pump pressure: Flow.

HVAC Simplified Online Training - By AMK. The following are hydraulic motor related equations for determining horsepower and related engineering design data. To determine a pumps horsepower use the following equation. Equation : Where: P = Power, hp Q = Flow Rate, gpm S = Specific Gravity of fluid H = Head height, ft = Efficiency coefficient. Pump power = flow rate x total differential head x liquid density x acceleration due to gravity ÷ pump efficiency How To Size A Pump Example Let’s look at an example to demonstrate how to size a pump.

Enter flowrate delivered by the pump (gallons per minute). Enter the total horizontal pipe length (feet) for your system. Select nominal pipe diameter (inches) using the pull-down menu. Enter total pumping lift or height (feet) water is pumped vertically. The head and flow rate determine the performance of a pump , which is graphically shown in the figure as the performance curve or pump characteristic curve.

You find it by dividing the total dynamic head (TDH) by the length of each stage. The TDH is the equal to the sum of the pumping level, head length, drop pipe friction loss and check value friction. Weisbach equation with the Moody diagram or the Colebrook or Swamee-Jain equation. If you need a pump to develop psi of water pressure, then buy a pump that develops feet of head. Allow me to refine a couple of points: Pumps develop differential head , or differential pressure.

The NPSHr is given by the pump manufacturer and is often shown on the pump curve. Net positive suction head available = absolute pressure head at the pump suction – liquid vapour pressure head. Pump Power Pumps are usually driven by electric motors, diesel engines or steam turbines. The “head” form of the Engineering Bernoulli Equation is obtained by dividing the energy form throughout by the magnitude of the acceleration due to gravity, g. We define the head developed by a pump as.

Pressure gauges typically incorporate scaled measurements whereas pump performance is measured by its head – ie what height it can pump a fluid to. It is therefore useful to be able to convert between the two measurements. Where Ht is the total head , Hd is the discharge head and Hs is the suction head.

Also be aware that this equation holds true whether the suction head is positive (level of liquid in the suction tank is above the pump ) or negative (level of the liquid in the suction tank is below the pump ). We can now go to the store and purchase a pump with at least feet of total head at gpm.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.