They are priority or use with deep excavations and where artesian water is present below an impermeable stratum. The riser pipes are connected to a header pipe which is connected to a vacuum pump. Pumping draws the groundwater into the well points , through the header pipe and then it is discharge typically to the stormwater system. A typical 1mm well-point dewatering pump is able to pump to 1well - points. This type of system generally consists of an array of pumping wells located near the excavation or slope.

The combined effect of the array lowers the groundwater table over a wide area. Normally, individual wells are spaced at distances of as much as meters. But soil conditions and the dewatering plan can cause spacing as close as just a few meters.

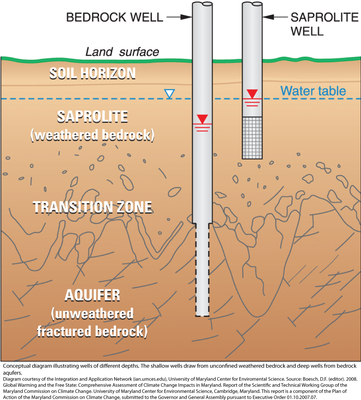

A variation of the typical deep well system is a pressure within an aquifer. Wells are normally formed by drilling, using either rotary drilling or percussion drilling methods. Once the well is drilled , a perforated well screen is installed and surrounded by filter gravel. For most dewatering systems the internal diameter of a deep well is in the range 1to 3mm.

The deep wells arrangement for the purpose of dewatering is similar to that for commercial water wells. By creating deep wells around the vicinity, the groundwater is made to fall into them under the influence of gravity. Deep Well Dewatering System. The deep well with vacuum assist is used in low permeability soils when typical wellpoint dewatering wells are too shallow to be used as a stand-alone method.

The small diameter deep well is drilled and installed with a submersible pump, like a normal well would be installed. The seal may be made with compacted clay, nonshrinking grout or concrete, bentonitic - mu or a short length of surface casing capped at the top. Wellpoint systems generally cost more than either sumps or wells, and require near-continual maintenance. A number of other dewatering techniques are available including ground freezing and electro-osmosis.

The eductor well method is a dewatering process used to control pore water pressures in materials with low permeability characteristics, such as fissured clays or silts. This method uses the venturi principle, where high pressure water is circulated through eductors in the base of each well to create a vacuum that helps promote drainage. This is preferable over a multi-stage well -point system. In case of a multi-stage well -point system ,. Dewatering systems are designed to lower the groundwater level to a specified depth to facilitate below ground construction. Monitor wells shall be installed where measurement of the effectiveness of the pumping is required.

Well point and deep well dewatering shall be terminated as soon as practical. In poorly drained soil areas, or where well dewatering is not practical, pumping directly from the construction trenches shall be allowed. Install deep well dewatering systems to given working instructions relating to the following: - locate and install or replace submersible pumps - install and connect pipe network - commission the system - monitor well parameters - monitor system and collect data - decommission the system. Dewatering equipment would have to be enough in size of pipes, machines, pumps etc.

Especially if the foundation type is mat foundation for high-rise building, it is necessary that dewatering shall be done before and during underground works. Here is the method statement for dewatering works. Our large, rotary bucket drill rigs combine with our line of electric submersible pumps to provide you with solutions that push water up from the bottom of the well and through a discharge piping system. Ejector Dewatering Ejector (or eductor) dewatering systems are used to control pore pressures and to lower groundwater levels to provide stable working conditions in excavations.

Ejector systems are able to extract groundwater and generate vacuum at the tip of wells and can be installed to depths in excess of 50-feet. A wellpoint dewatering system consists of a series of shallow wells, known as wellpoints, which are installed at a pre-determined depth and appropriate spacing around an excavation. The wellpoints are connected to the surface, via a riser pipe, and in turn, connected to a common header main pipe through a flexbow.

A deep well typically consists of a borehole fitted with a slotted liner and an electric submersible pump. As water is pumped from a deep well , a hydraulic gradient is formed and water flows into the well forming a cone of depression around the well in which there is little or no water remaining in the pore spaces of the surrounding soil.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.