What are the main parts of centrifugal pump? What is the difference between centrifugal pumps? There are a few components that virtually every centrifugal pump has in common.

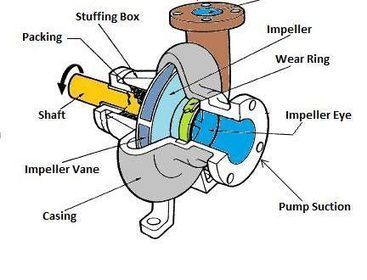

Each centrifugal pump is made of hundreds of parts. These components can be subdivided into the wet end and the mechanical end. Casing: The outer shell of the pump that protects components from the outside elements is call pump casing. The two main components of a centrifugal pump are the impeller and the volute.

The centrifugal pump is simple in construction than the reciprocating pump. Because the centrifugal pump has less number of parts. Where reciprocating pump has less weight of pump for a given discharge.

Centrifugal Pump Components. So today we will study the centrifugal pump and its Main parts , Working principle, and Application, PDF. Here You will get the articles of Mechanical Engineering in brief with some key points and you will get to know an enormous amount of knowledge from It. Each part or component in a pump plays a very crucial role in its efficient functioning.

Water Pump s Direct - We Make Buying Technical Products Simple. Fast and Free Shipping On Many Items You Love On eBay. But actual centrifugal pumps were not discovered until 17th century.

We will discuss the components of centrifugal pump by starting from suction and will end at delivery of fluid at reservoir Suction Suction pipe Pipe which lifts the liquid from the sump and provides it to the pump at the impeller eye is called suction pipe. Suction is made air tight in order to stop the formation of air pocket with in the pump. We look at all of the centrifugal pump ’s main components and briefly discuss how it works. The volute casing, diffuser, impeller, wear. The diagram shows the main parts of the centrifugal pump.

The shaft passes through the pump casing and out through the stuffing box (portion of the casing through which the shaft extends and where seal or packing is placed). The impeller is fastened to the shaft. Our pump replacement parts are equal to or better than, your original equipment and our prices are definitely better!

This type of pumps uses the centrifugal force created by an impeller which spins at high speed inside the pump casing. Some of the viscosities liquids at 680F -700F will require extra horsepower to work the centrifugal pumps. A centrifugal pump utilizes rotation to pass on velocity in the direction of the fluid.

When a pump breaks down, sometimes buying replacement parts or components is an alternative to buying a new pump. The casing of the pump should be of materials. These lighter-weight pumps also offer lower investment costs and reduced parts expense.

As well depths increase so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.