How do you calculate friction factor? What units is head loss in? If the value of the friction factor is 0. At constant flow rate and pipe length, the head loss is inversely proportional to the 4th power. Darcy Friction Factor Consider that the length of the pipe or channel is double the resulting frictional head loss will. Since the head loss is roughly proportional to the square of the flow.

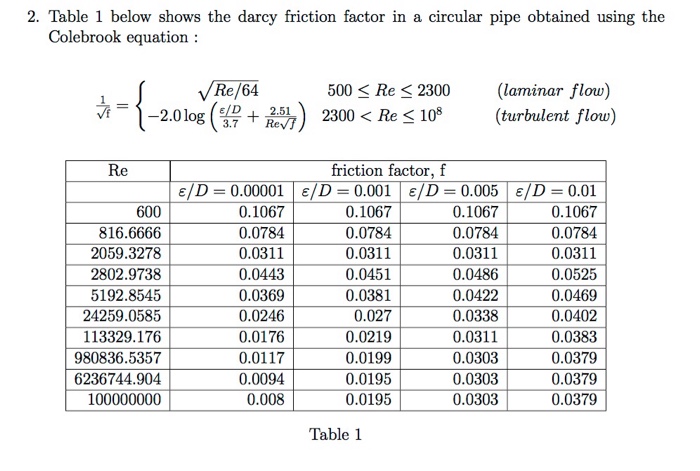

This is also called the Darcy–Weisbach friction factor , resistance coefficient , or simply friction factor. The Reynolds number is calculated with the equation Re= VD (3) where V is the ow velocity and the kinematic viscosity of the uid. Darcy friction factor e roughness of the pipe D inner diameter of the pipe Re the Reynolds number The ratio e=Dis called the relative roughness.

The Moody friction factor (f) is used in the Darcy-Weisbach major loss equation. Note that for laminar flow, f is independent of e. However, you must still enter an e for the program to run even though e is not used to compute f. Equations can be found in Discussion and References for Closed Conduit Flow. The friction factor , which is used in the Darcy Weisbach equation, depends upon the Reynolds number and the pipe roughness. Fully Develope Turbulent Flow The Darcy Weisbach Equation applies to fully develope turbulent pipe flow.

It gives the relation between velocity of liquid in pipe,length of pipe ,and Diameter of pipe. One unified platform to run your entire business. Infant Growth Charts - Baby Percentiles Overtime Pay Rate Calculator Salary Hourly Pay Converter - Jobs Percent Off - Sale Discount Calculator Pay Raise Increase Calculator Linear Interpolation Calculator Dog Age Calculator Ideal Gas Law Calculator Fluid Pressure Equations Calculator Darcy -Weisbach Equations Calculator Colebrook Friction Factor. To have a direct expression, with an acceptable accuracy, you can use Churchill equation.

The most common method to determine a friction factor for turbulent flow is to use the Moody diagram. In Fluid Mechanics, the Moody chart or Moody diagram is a graph which relates the Darcy -Weisbach friction factor (f D ), Reynolds number (Re), and surface roughness for fully developed flow in a circular pipe. It can be used to predict pressure drop or flow rate down such a pipe. It is also known as friction loss. The Darcy -Weisbach method is generally considered more accurate than the Hazen-Williams method.

It represents the interaction in between the fluid and the pipe. There are different ways to calculate it, one can be graphical, using a Moody graph, but for automating calculation it is not practical, thus correlations are required. Haaland of the Norwegian Institute of Technology. Friction factor (μ) is defined as the ratio between the force required to move a section of pipe and the vertical contact force applied by the pipe on the seabed. This simplified model (Coulomb) is used to assess stability.

In terms of head units it is, (pipe friction ) where, h l is the head loss, f is the friction factor , L is the pipe length, V is the average flow velocity, and g is the acceleration of gravity. Fanning-friction-factor : The Fanning friction factor, named after John Thomas Fanning, is a dimensionless number, that is one-fourth of the Darcy friction factor. The Colebrook (or Colebrook-White) equation is the best way to dynamically determine the Darcy -Weisbach friction factor for turbulent pipe flow.

The equations were developed via a curve fit to many experimental data points. In the post below, I demonstrate how to create a Colebrook equation solver in Excel. The Darcy Friction factor (which is times greater than the Fanning Friction factor ) used with Weisbach equation has now become the standard head loss equation for calculating head loss in pipes where the flow is turbulent. which Moody plotte and the Fanning friction factor f.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.