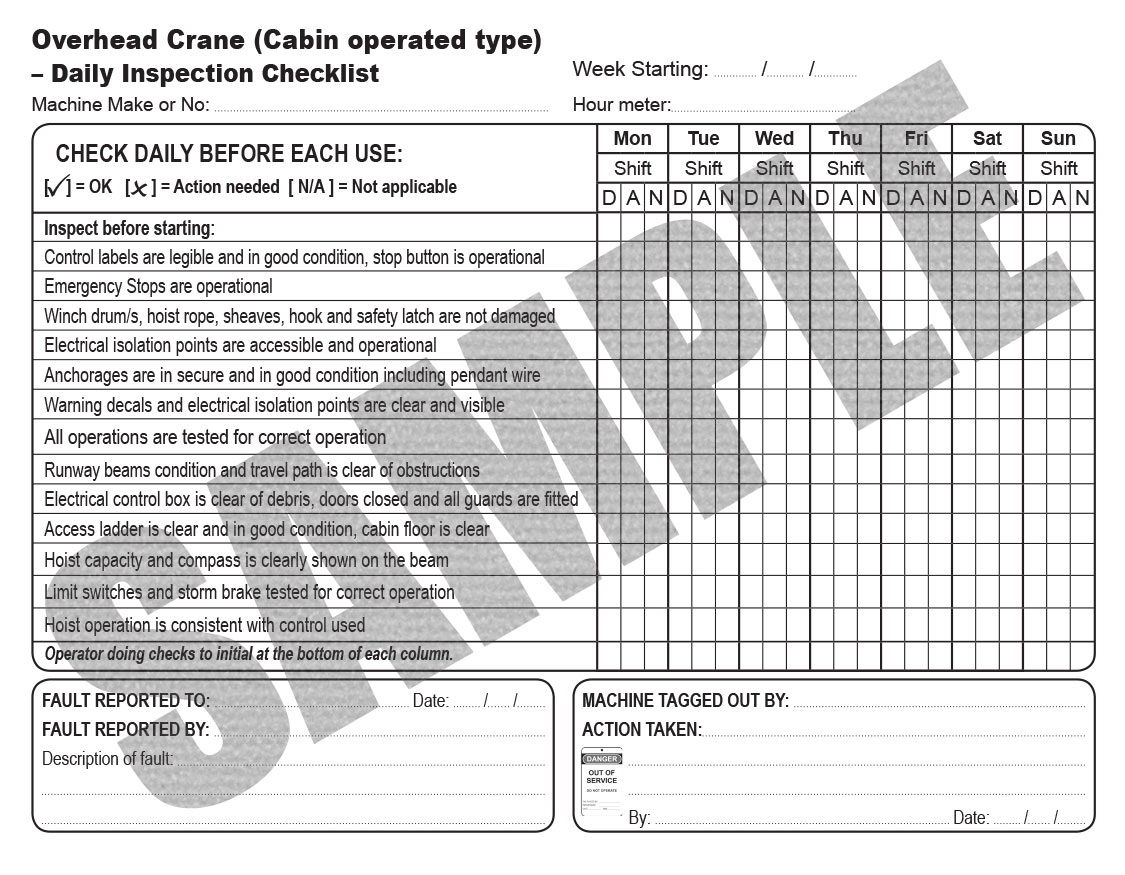

Request a Free Sample Pack Today! All Our International Locations. Any Of Our Products Contact Us Now. Department of Labor ( OSHA ). PREVIOUS EDITIONS ARE OBSOLETE. INSTRUCTIONS: Before first use of the day, inspect all applicable items.

This OSHA overhead and gantry crane checklist converted through iAuditor is used to ensure operators comply with mandated safety regulation. Use iAuditor to perform a digital inspection that thoroughly checks the crane equipment and its electrical connections. These documents contain customizable inspection checklists for cranes in general industry and the construction industry.

Load lifting devices must be inspected regularly following suggested checklist attached. Minimum crane clearances must include inches overhead and inches laterally. Overhead _and_Gantry_ Crane _ Inspections. Outdoor cranes must be equipped with a visib le or audible wind velocity detector.

Items stored in the cab must be secured at all times. CRANE INSPECTION REPORT Prior to initial use, all new and altered cranes should be inspected to determine if any safety hazards exist. Thereafter, inspections should be performed at intervals according to the following list.

Some components require daily inspection , while others need only be checked on a monthly basis. Our free documents help you prepare shift, monthly and annual checklists for crane inspections. To ensure the effectiveness of these daily inspections , we’ve created an overhead crane inspection checklist. Download a free copy of our checklist to help maintain compliance with OSHA requirements. What is an inspection checklist?

Our checklist will help you prepare the basic requirements for the overhead crane inspections and overhead crane safety. Find these OSHA crane safety requirements: general, design, inspection , maintenance and operation. Customise the crane inspection checklist for overhead cranes , truck mounted cranes , jib cranes , gantry cranes or tower cranes to suit your own projects and company with easy drag-and-drop functionality. Instantly format your completed crane inspections into timeline view or register view to save time and find any record instantly. These safety checklists are designed to help improve safety, reduce maintenance costs and ensure compliance with legal responsibilities.

RANE OPERATOR’S PRE-SHIFT SAFETY INSPECTION CHECKLIST. A programme of pre-use checks, regular inspections and servicing schedules should be established in accordance with the manufacturer’s instructions and the risks associated with using an overhead crane. Checklists for the inspection and testing of tower and mobile cranes including for major inspections and tower crane pre-erection and commissioning inspections are at. Before operating a crane a pre-operational check should be completed by a competent. This crane pre-use inspection checklist template comes pre-built with a bunch of questions which are applicable to overhead cranes , as well as others, and also features sections for flagging who was responsible for the inspection , the time and the date, any outstanding corrective actions and a digital sign off.

An operational overhead crane helps keep your business running, while a failed crane can shut it down. Safety Inspection Requirements. UNUSUAL SOUNDS Check for any unusual sounds from the crane or hoist mechanism during operation. OIL LEAKAGE Check for any sign of oil leakage on the crane and on the floor beneath the crane.

HOIST CHAIN Check for cracks, nicks, gouges, wear and stretch. Crane U provides the best overhead crane inspection you can get for the money! We take no shortcuts and keeping your crane operators and crew safe is our number one priority.

Daily Operator Inspection Reuirements Tagged Crane or Hoist Check that the crane or hoist is not tagged with an outan out-of-order signorder sign. Crane Inspections and Preventive Maintenance Konecranes certified inspectors and trained technicians provide an accurate assessment of the condition of your equipment. They evaluate risks, identify improvement opportunities and provide recommendations.

An active preventive maintenance program is crucial to improving safety and productivity.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.